It consists of gathering and analyzing data on all features and stages of the producing process. This includes:

On the subject of the necessity of process validation, it can not be overstated. It ensures that a process is effective at constantly making items that satisfy the specified quality and overall performance requirements.

Checking Critical Parameters: Steady monitoring of important process parameters and in-process controls would be the cornerstone of concurrent validation.

A efficiency qualification template is employed to finish the process validation protocol by detailing how the tools/process is continuously Conference performance conditions for routine use in professional output. This process validation protocol – functionality qualification template describes a sample aim, scope, and duty to really make it a lot easier for validation supervisors to accurately carry on While using the tools/system run.

The basis by which process parameters and good quality characteristics are determined as currently being crucial or non-essential need to be Evidently documented, taking into consideration the effects of the risk assessment pursuits.

The U.S. Food items and Drug Administration (FDA) has proposed guidelines with the next definition for process validation: – “PROCESS VALIDATION” is establishing documented proof which presents a large degree of assurance that a certain process regularly generates an item Conference its predetermined specifications and high-quality attributes.

The business process process validation examples is described all through this stage based upon information received via advancement and scale-up actions.

The template includes sections to the introduction, scope, methodology, final results, conclusions and suggestions. The introduction normally incorporates qualifications specifics of the process, the scope defines what's going to be lined inside the validation exertion, the methodology outlines the methods used to validate the process,. Eventually of your audit you can access a vehicle-produced report that may consist of the outcome in the validation, as well as the conclusions and proposals summarize the validation success and supply ideas for any important alterations.

Retrospective validation is useful for amenities, processes, and process controls in Procedure use which have not undergone a formally documented validation process. Validation of such amenities, processes, and process controls can be done making use of historical information to supply the necessary documentary proof which the process is performing what it's believed to do.

Modifications to your plant format, environmental controls, or production places call for revalidation to take care of compliance with regulatory criteria and forestall contamination dangers.

Continued Process Verification (CPV) is the final phase of process validation, which makes certain the process stays validated through business generation. This stage requires ongoing monitoring, data selection, and periodic assessments to take care of the integrity with the production process.

verification and validation will not be precisely the same matter as style verification and validation. The latter are carried out as Section of structure controls, and possess their unique unique definitions and ways.

FDA defines process validation as “establishing by aim proof that a process continually creates a outcome or item Assembly its predetermined specifications.”

With this phase, the process is intended and documented in detail. The vital read more process parameters as well as corresponding functioning ranges are recognized.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Tia Carrere Then & Now!

Tia Carrere Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Brian Bonsall Then & Now!

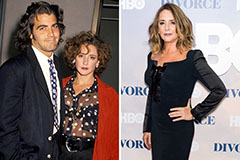

Brian Bonsall Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now!